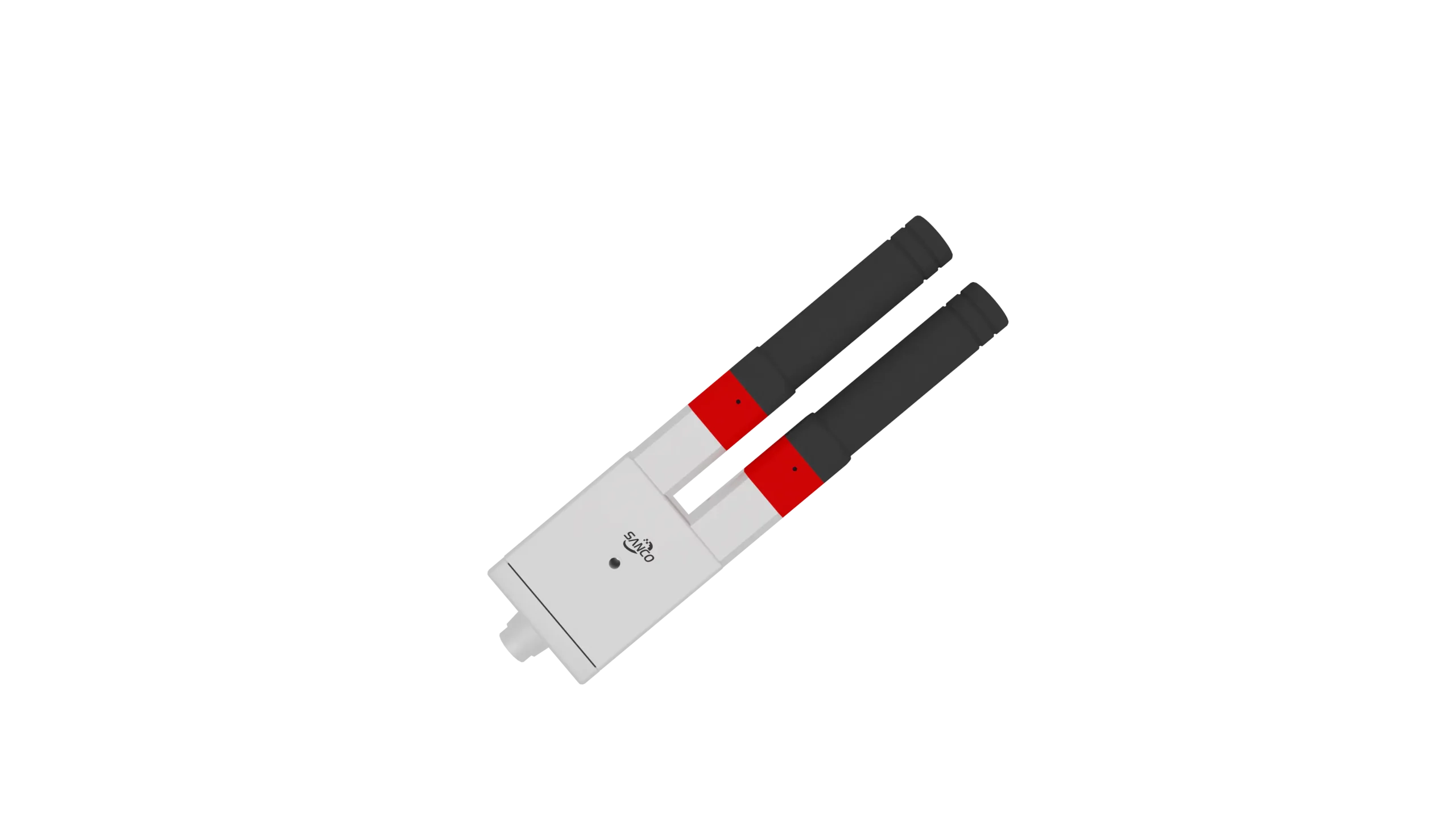

Dispensing Valve

Dual Liquid Screw Valve

Two-component precision screw valve with constant output flow, pulsation-free and low shear delivery, perfect for mixing and dispensing dual liquid materials up to 8,000,000cps.

Principle

The structure is combined with rotor and the stator. The liquid in the closed space is transported forward by the rotor rotation. When the rotor rotates continuously in the stator cavity, it moves smoothly and uniformly from the suction end of the pump to the discharge end due to the action of pressure, thus completing the stable delivery of the liquid medium.

KEY FEATURES

Advanced dual screw valve technology for precise two-component dispensing

Constant Output Flow

Output flow constant, smoothly, pulsation-free and low shear for consistent two-component dispensing.

Accurate Measurement

Flow error < 1%, repeatability > 99% for precise and repeatable dual liquid operations.

Adjustable Ratio

The ratio can be adjusted by adjusting the motor speed, from 1:1 to 10:1 according to requirements.

Ultra-Micro Flow

Applicable to various ultra-micro flow occasions, minimum trace amount can reach 0.001mL.

High Viscosity Compatible

Suitable for all kinds of high viscosity, high solid granular fluids, up to 8,000,000cps.

Stable Output

Output flow is proportional to rotational speed, unaffected by medium viscosity, pressure, or temperature.

Anti-Dripping Design

Through the opening and closing valve, liquid dripping and wire drawing is perfectly avoided.

Simple Structure

Easy to disassemble, easy to clean, easy to assemble for convenient maintenance.

Specification

Complete technical specifications for all model variants.

| Item | PCD-015 | PCD-050 | PCD-150 | PCD-500 | PCD-1500 | PCD-2000 |

|---|---|---|---|---|---|---|

| Dimension | 30 × 60×L275 | 30×60×L290 | 30×60× L300 | 30×60×L300 | 45× 90×L550 | 60× 120×L720 |

| Weight | 1000g | 1050g | 1100g | 1100g | 5.2kg | 7.5kg |

| Viscosity | 0-500,000cps | 0-500,000cps | 0-500,000cps | 0-500,000cps | 0-500,000cps | 0-500,000cp |

| Glue volume per rotation | 0.015ml | 0.05ml | 0.15ml | 0.50ml | 1.5ml | 2.0ml |

| Glue speed (MAX) | 1.8ml/min | 6.0ml/min | 20ml/min | 60ml/min | 225ml/min | 300ml/min |

| Maximum input pressure | 0-6kgf/cm² | |||||

| Maximum output pressure | 20kgf/cm² | |||||

| Speed (rpm) | 1-120rpm | 0-150rpm | ||||

| Precision control | 1% | |||||

| Stator material | Ceramics | |||||

| Contact glue material | SUS/PE/FKM | |||||

| Ambient temperature | 0-40°C | |||||