Dispensing Machine

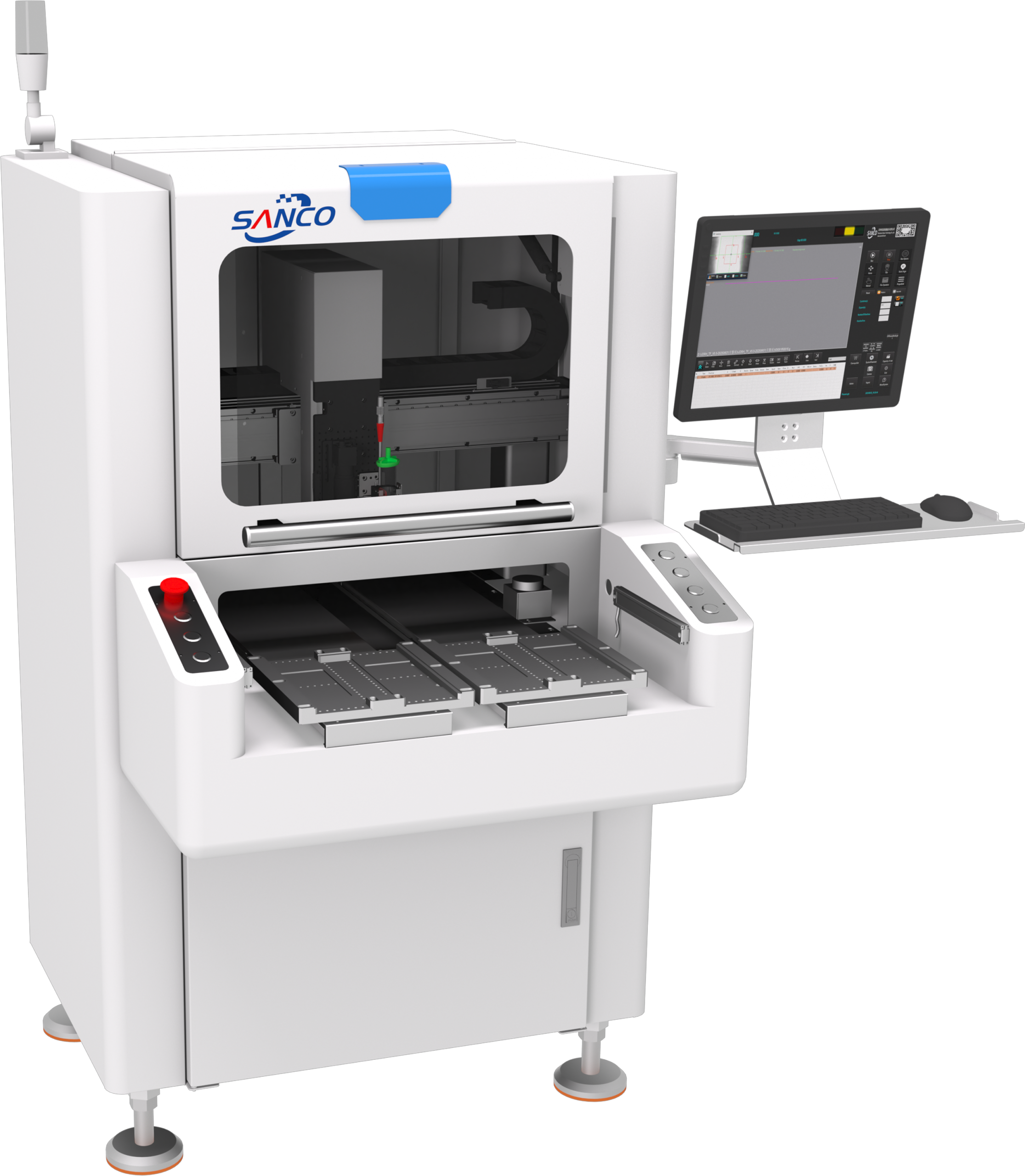

DS Series Inline High Speed Dispensing Machine

Professional inline dispensing solution with CCD vision positioning, servo motor control, and automatic temperature system for consistent high-precision dispensing in production lines.

Product Description

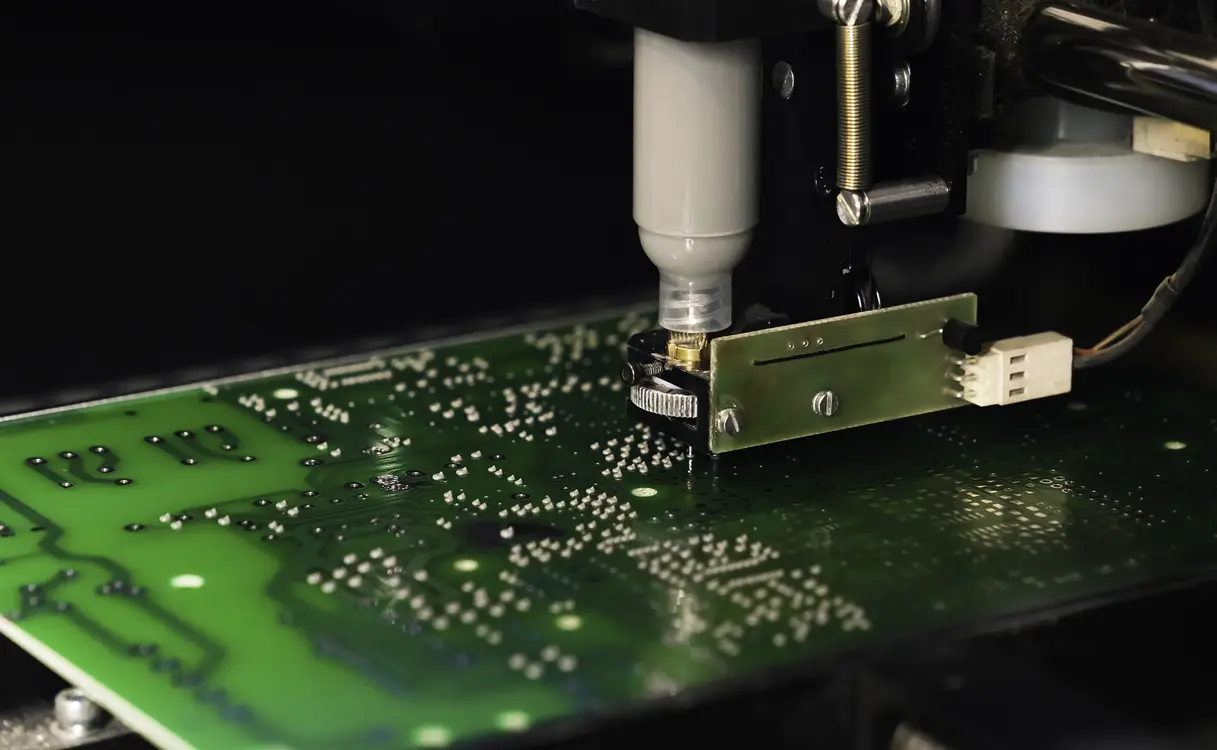

The DS Series Inline High Speed Dispensing Machine is designed for seamless integration into production lines, offering professional motion control and high-quality module structure for high-speed and high-precision operation.

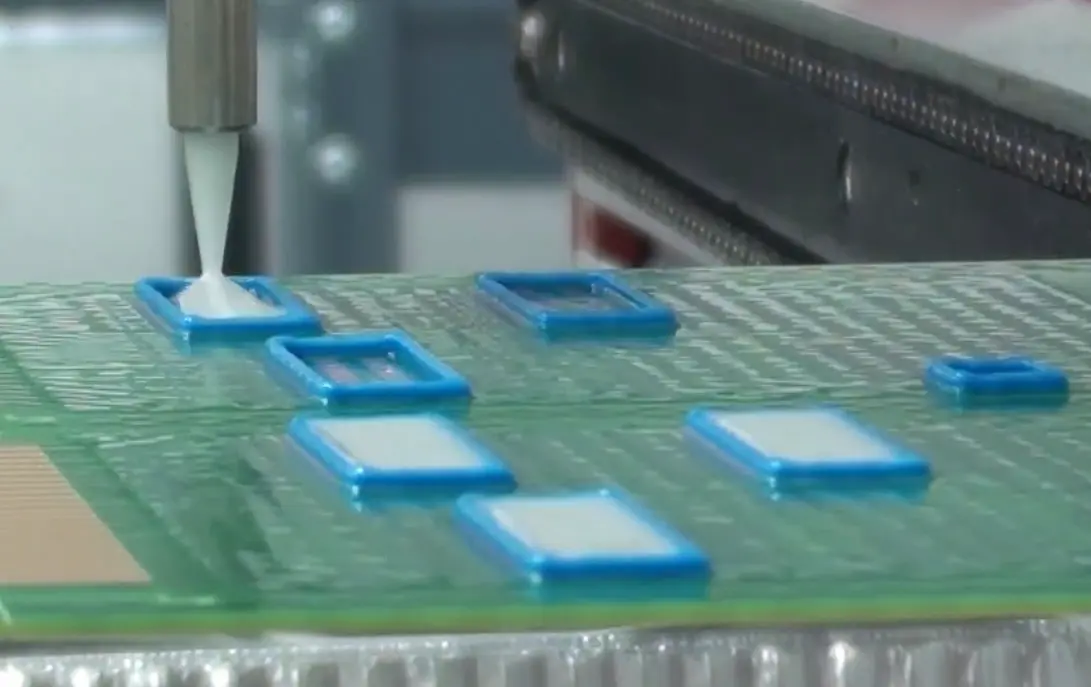

Featuring Windows operating system control, CCD vision positioning, and automatic constant temperature system, this machine ensures consistent fluidity of paint and optimal dispensing results for demanding manufacturing applications.

KEY FEATURES

Advanced technology for professional inline dispensing applications

Windows Control System

Computer control with Windows OS, fault sound and light alarm and menu display

CCD Vision Positioning

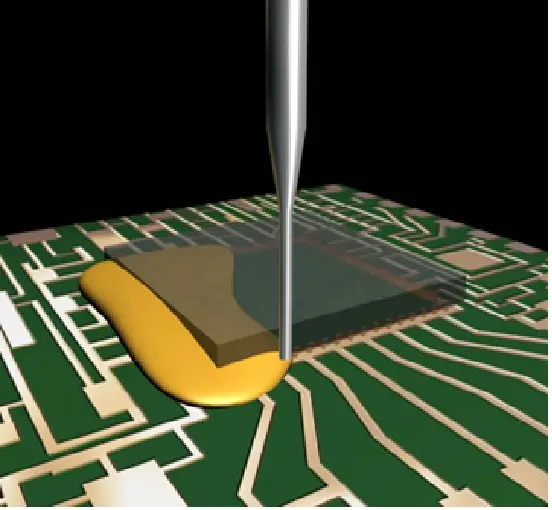

Advanced CCD vision positioning system for precise alignment and dispensing accuracy

Servo Motor + Motion Card

Using servo motor for XYZ + motion control card for high-speed precision operation

Professional Motion Control

High-quality module structure for high-speed and high-precision operation

Cast Iron Chassis

Cast iron chassis and gantry provide strong guarantee for stability of operation

Multiple Valve Options

Compatible with pneumatic injection valve, piezoelectric valve, screw valve, etc

Auto Temperature System

Automatic constant temperature system of valve body ensures consistent fluidity

Flexible Programming

Import any brand of placement machine files, or online visual programming

Laser Height Detection

Optional laser height detection for automatic Z-axis calibration after workpiece deformation

Workpiece Heating

Optional workpiece heating system to enhance paint fluidity during underfilling

Applications

Precision dispensing solutions for diverse manufacturing needs

Detailed Parameters

Complete technical specifications for all model variants.

| Item | Specification and description |

|---|---|

| Model No. | DS-600 |

| Dimension | L = 1000mm*W = 1200mm*H1700mm |

| Net weight | 560kg |

| Control | IPC+Motion control card |

| Software | Sanco software+Windows |

| Program | SMT file or online vision programming |

| Number of spindles | X Y Z |

| Spindle drive | Servo motor X Y Z |

| Distance Range | X:600 Y:400 Z:50mm |

| Valve quantity | 1 pcs(Standard) |

| Maximum Speed | 800mm/s |

| Repeatability accuracy | ±0.02mm |

| Paint volume | 300CC/30CC |

| Paint detect | Auto detection |

| Interface | SMEMA |

| Direction | left→right(Standard)⎕right→left |

| Valve cleaning device | Vacuum cleaning |

| Alarm | Menu + sound and light alarm |

| Conveyor | Belt conveyor |

| Speed | stepper motor 2-5m/min |

| Width | 50-400mm |

| Power suppy | 220V 50/60HZ |

| Air pressure | ≥0.65Mpa |

| Safety standard | CE |

| Total power | 2.5KW |

| Standard function | CCD visual positioning |

| LED | |

| Electrostatic interface | |

| 232 interface | |

| Jacking device |

Featured Dispensing Equipment:

Precision from a Top Glue

Dispensing Machine Manufacturer

Read More

LM series Inline High Speed Dispensing Machine

Read More →

Offline High Speed Dispensing Machine

Read More →

Desktop Visual Dispensing Machine

Read More →

DS series Inline High Speed Dispensing Machine

Read More →

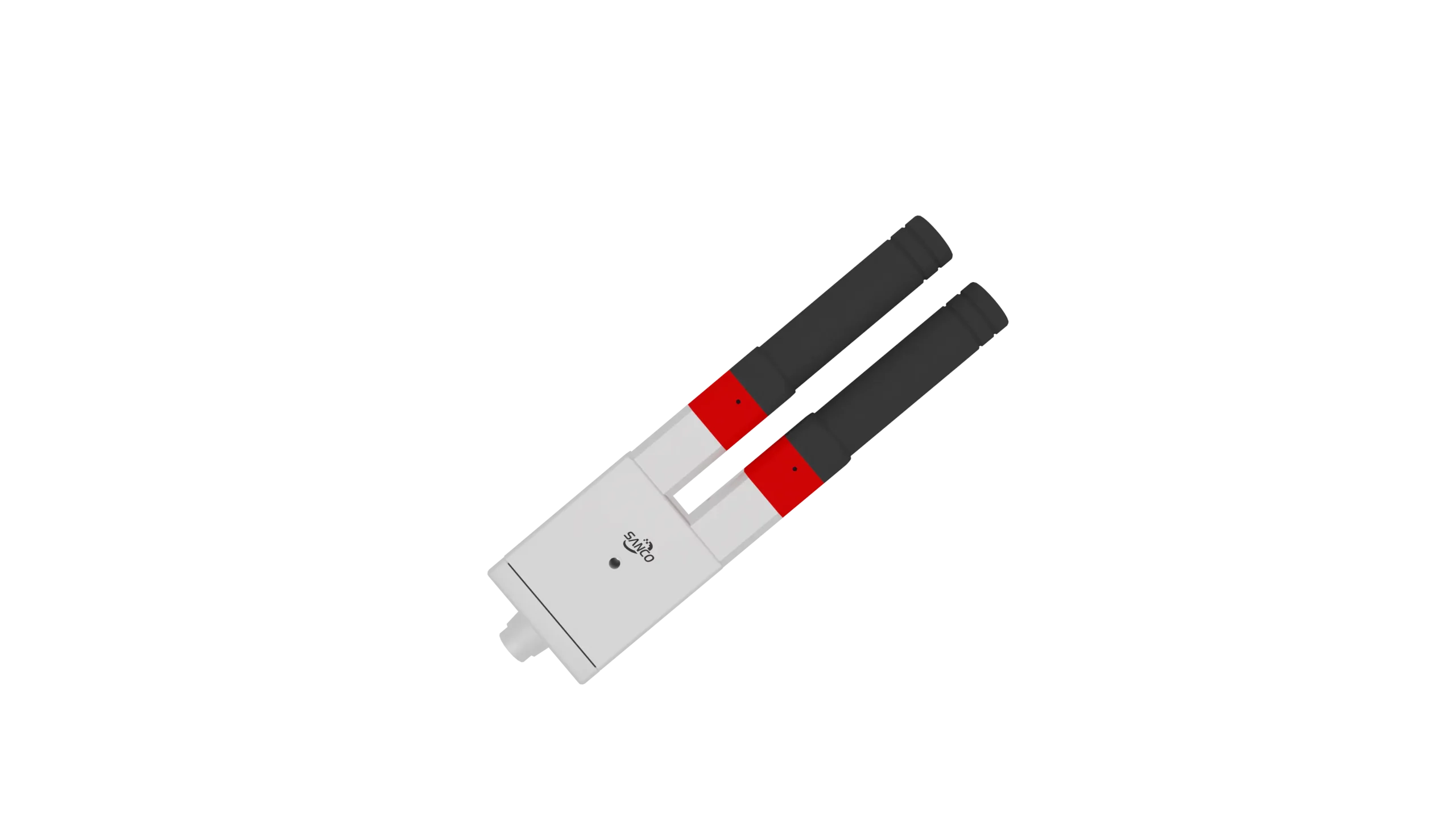

Piezo Valve

Read More →

Piezo Valve

Read More →

Piezo Valve Controller

Read More →

Single Liquid Screw Valve

Read More →

Dual Liquid Screw Valve

Read More →

CANP 5G Pump

Read More →