Dispensing Machine

Desktop Visual Dispensing Machine

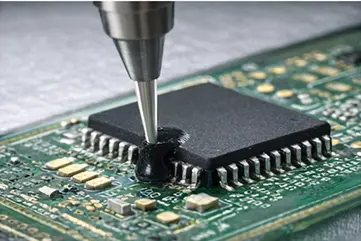

The desktop visual dispenser adopts special operating software, supporting a new type of vision system technology, and special glue dispensing vision software to ensure the accuracy of the dispensing process.

Product Description

The desktop visual dispenser adopts special operating software, supporting a new type of vision system technology, and special glue dispensing vision software to ensure the accuracy of the dispensing process.

With the jet valve, it can realize non-contact jet dispensing, achieve a smaller dispensing diameter, and a wider application field. Perfect for precision electronics manufacturing and component assembly.

KEY FEATURES

Advanced technology and precision engineering for reliable desktop dispensing

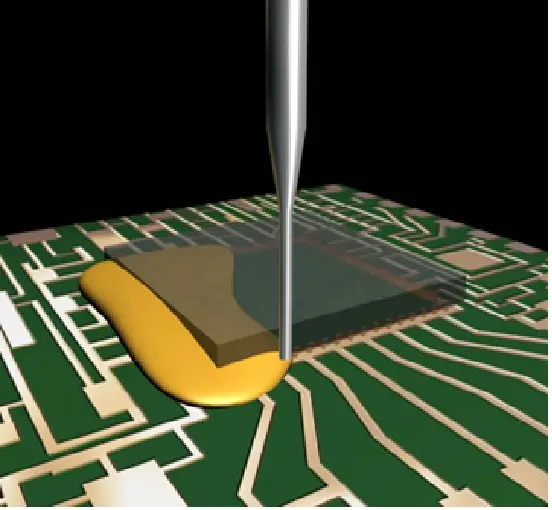

Non-Contact Jet Dispensing

With the jet valve, it can realize non-contact jet dispensing, achieve a smaller dispensing diameter, and a wider application field

Template Matching Vision

Template matching, edge recognition and other visual recognition methods, which can adapt to products of different shapes, color and materials

Stainless Steel Mirror Case

Optional all stainless steel mirror case to meet the requirements of 100-level dust-free production environment

Excel-Style Interface

Excel-style program line editing interface, simple and user friendly for easy operation and programming

Automatic Calibration

Automatic calibration and visual programming, suspended graphic track preview for precise positioning

Direct Pulse Control

Valve control enables direct pulse control for on-the-fly dispensing, point count and glue volume control

Rotation Module

Optional with the rotation module which can realize tilt or rotate dispensing for complex geometries

Linear Motor Drive

Optional linear motor drive, positioning accuracy up to ±10μm for ultra-precise applications

Applications

Versatile dispensing solutions for diverse manufacturing requirements

Detailed Parameters

Complete technical specifications for all model variants.

| Item | Specification and description | ||

|---|---|---|---|

| DV250 | DV300 | DV325 | |

| Model No. | DV250 | DV300 | DV325 |

| Dimension | L = 600mm W = 600mm H = 650mm |

L = 650mm W = 650mm H = 650mm |

L = 650mm W = 850mm H = 650mm |

| Net weight | 75kg | 85kg | 120kg |

| Control | IPC+Motion control card | ||

| Software | Sanco software+Windows | ||

| Number of spindles | X Y Z | ||

| Spindle drive | LinearElectric Motor XY servo motor Z | ||

| Distance Range | X:250 Y:250 Z:50(mm) | X:300 Y:300 Z:50(mm) | X:300 Y/1 Y2:250 Z:50(mm) |

| Valve quantity | Piezo valve Standard | ||

| Maximum Speed X/Y/Z | 800mm/s X/Y 300mm/s Z | ||

| Visual positioning system | 5 mega-pixel industrial camera | ||

| Resolution(mm/pixel) | 0.01*0.01(adjustable) | ||

| Recognition range(mm) | 14*14 (Depending on the selected lens) | ||

| Light source | LED light source (ring light, coaxial light optional) | ||

| Repeatability accuracy | ±0.01mm | ||

| Paint volume | 30CC | ||

| Power suppy | 220V 50/60HZ | ||

| Air pressure | ≥20.65Mpa | ||

| Total power | 1.5KW | ||