Curing Oven

Vertical Oven

Vertical heating curing furnace for semiconductor, SMT, dispensing and glue filling industries. 3D heating space design with energy saving, equivalent to 20-35m tunnel furnace.

Product Description

This equipment is a vertical heating curing furnace developed for semiconductor, SMT, dispensing and glue filling industries. It changes the plane heating space into a three-dimensional heating space, and has the advantages of saving energy consumption and space.

Perfect alternative to tunnel furnace, the efficiency of this equipment is equivalent to 20-35m tunnel furnace. The equipment adopts embedded system, which is different from ordinary touch screen and industrial computer, it is not only stable and reliable but also has richer and more convenient communication interfaces.

Product Direction

Advanced structural design for optimal performance

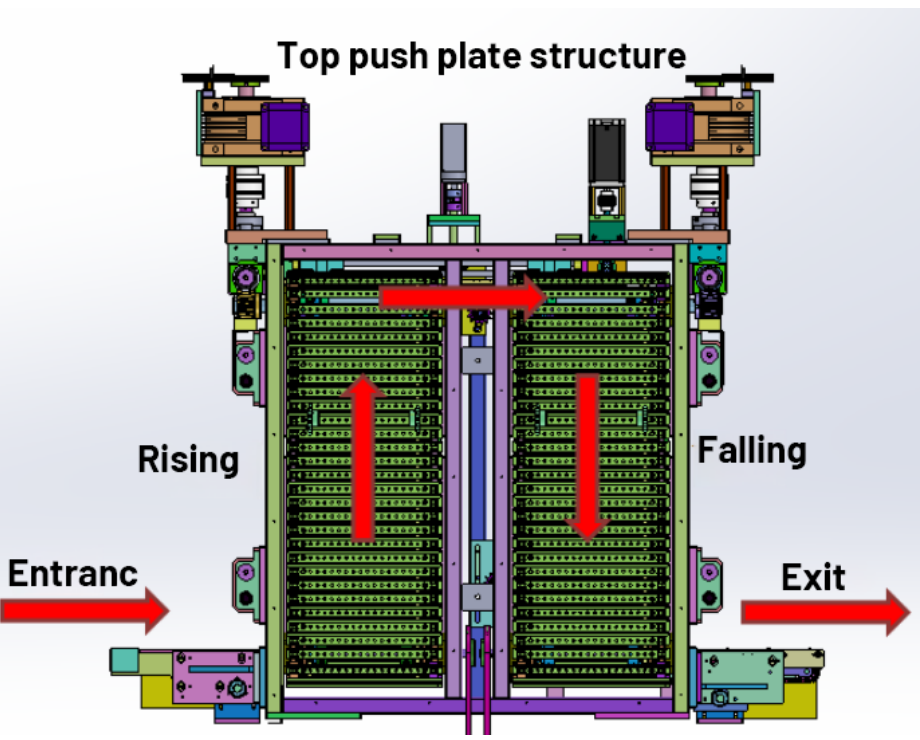

Top Push Plate Structure

Innovative top push plate design with entrance, rising, falling and exit cycle for efficient product handling.

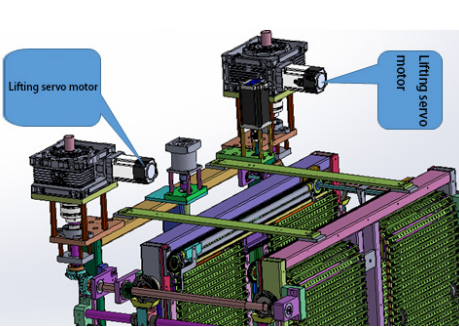

Lifting Servo Motor

Controlled by servo motor through encoder, with high position & speed control accuracy. Strong overload capacity for high load and dynamic response.

Optical Fiber

High-temperature optical fiber moves accurately, avoiding PCB from jamming and dropping caused by motor step loss and mechanical cumulative errors.

Slots Added in Support Bar

The transporting slot can directly clamp the support bar, which can only move in the slot. Therefore the chain doesn't get tangled, runs more stable. It is one of our patents.

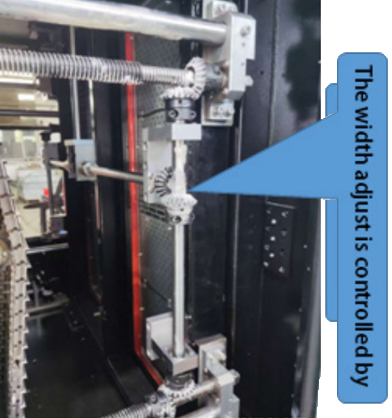

Width Adjust by Gear Structure

The bevel gear width adjustment is more synchronized than traditional chain width adjustment, with better parallelism, which prevents PCB from dropping.

KEY FEATURES

Advanced vertical curing technology for superior results

3D Heating Space

Changes plane heating space into three-dimensional heating space, saving energy and space.

Tunnel Furnace Alternative

Efficiency equivalent to 20-35m tunnel furnace in a compact vertical design.

Embedded System

Different from ordinary touch screen, more stable with richer communication interfaces.

Dual Temperature Zone

Real dual temperature zone design for both heating and cooling in one system.

Servo Motor Chain

Transportation chain driven by servo motor with thermal expansion compensation.

MES Remote Data

Supports formulation function of key welding parameters and MES remote data reading.

Unique Air Handling

Level + up and down air handling, effectively prevents inadequate air handling.

Level 3 Protection

Level 3 protection to effectively prevent product damage due to over temperature.

Dust-Free Design

Equipment is designed to be dust-free and can be applied to any dust-free place.

Intelligent PID Fuzzy

Intelligent PID fuzzy operation for stronger thermal compensation and lower energy consumption.

Related Products

Explore other curing and dispensing equipment

Specification

Complete technical specifications for all model variants.

| Model | SVT-250 | SVT-450 | SVT-650 |

|---|---|---|---|

| Dimension(mm) | L1700*W1920*H2150 | L2100*W2120*H2150 | L2900*W2320*H2150 |

| Weight | Approx.1500kg | Approx.1800kg | Approx.2100kg |

| W*L Max. PCB size | 300*250 mm | 400*450 mm | 600*650 mm |

| Product weight | Max. 3kg/layer | ||

| Component height | 25.4mm | ||

| PCB process edge | 5mm | ||

| Number of layers | 60 layers | ||

| Conveyor height | 900±30mm | ||

| Min. output | 12s/pcb&pallet | ||

| Entrance& exit conveyorW | In-line | ||

| Lifting system | Servo motor | ||

| Rail width adjustment | Manual or Automatic | ||

| Setting temperature | Max. 250°C | ||

| Heating system | 4*2=8 heating modules | ||

| Heating power | 8*6KW | 8*8KW | 8*9KW |

| Temperature control accuracy | ±1°C | ||

| Inner temperature difference | Less than ±2°C | ||

| N2 configuration | Optional | ||

| Cleanroom class | Optional | ||