Dispensing Valve

Piezo Valve

High-speed piezoelectric jet dispensing valve with ultra-fast response time, enabling non-contact precision dispensing for advanced electronics manufacturing applications.

Product Description

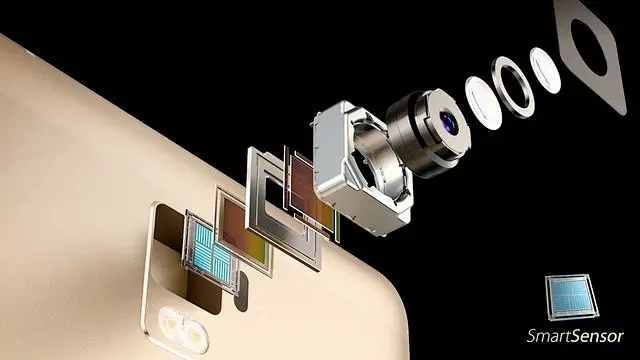

The Piezo Valve utilizes advanced piezoelectric technology to achieve ultra-fast, non-contact jet dispensing. This innovative valve delivers exceptional precision and repeatability for demanding electronics manufacturing applications.

With its high-frequency operation capability and precise volume control, the Piezo Valve is ideal for applications requiring micro-dispensing of adhesives, solder paste, underfill materials, and other precision fluids.

KEY FEATURES

Advanced piezoelectric technology for superior dispensing performance

Piezoelectric Actuation

Advanced piezoelectric element provides ultra-fast response and precise displacement control for consistent dispensing.

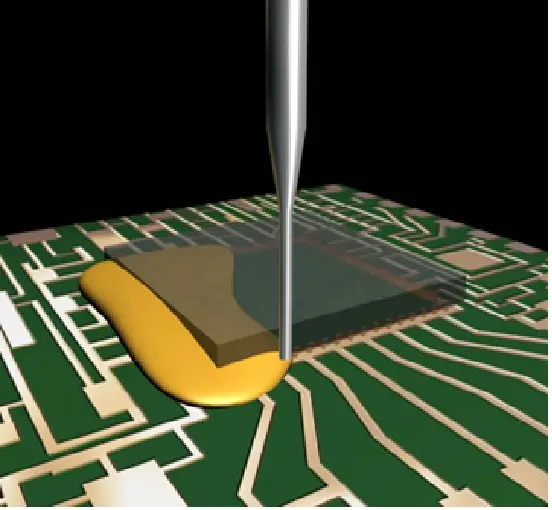

Non-Contact Dispensing

Jet dispensing technology eliminates surface contact, reducing contamination risk and enabling 3D dispensing paths.

High-Speed Operation

Capable of dispensing at frequencies up to 1000Hz, dramatically increasing production throughput.

Precise Volume Control

Nanoliter-level dispensing accuracy with exceptional repeatability for demanding micro-dispensing applications.

Wide Fluid Compatibility

Compatible with various fluids including adhesives, solder paste, underfill, silver paste, and more.

Easy Maintenance

Modular design allows for quick cleaning and maintenance, minimizing production downtime.

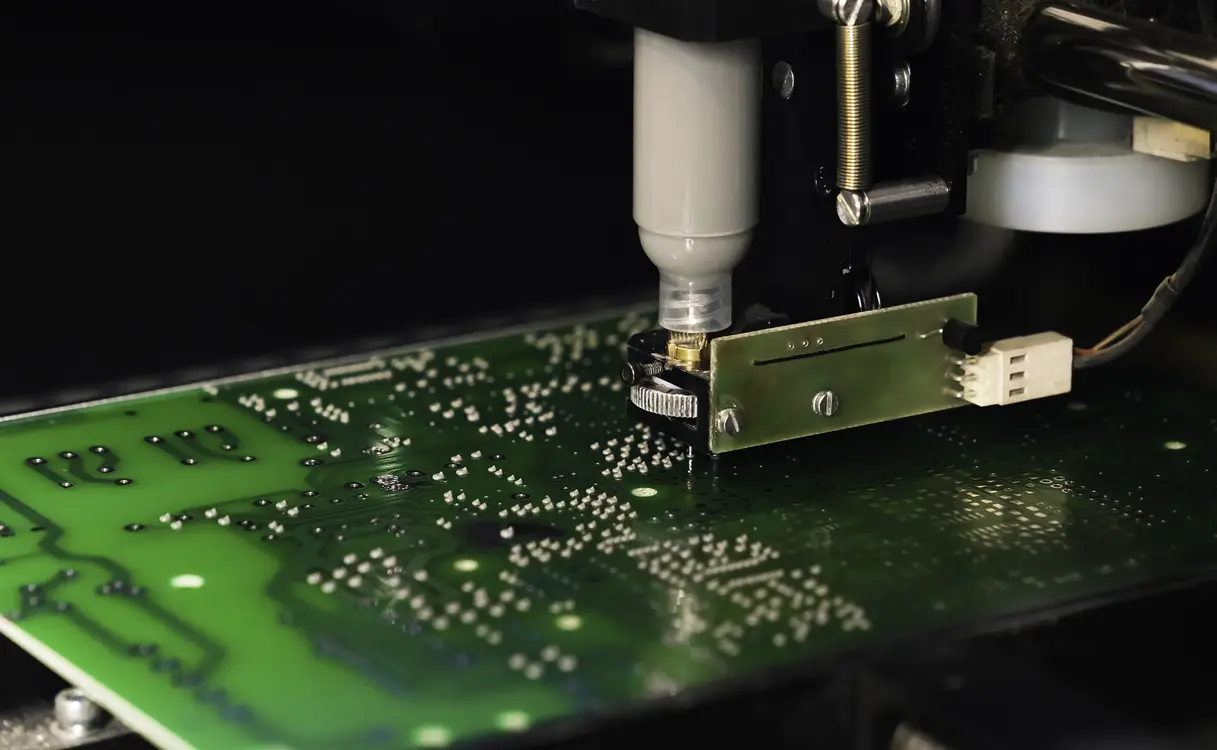

Applications

Precision dispensing solutions for advanced manufacturing

Technical Specifications

Detailed specifications for Piezo Valve

Related Products

Explore other dispensing valves and controllers

Ready to Upgrade Your Dispensing?

Contact our experts to discuss your precision dispensing requirements and find the perfect valve solution.

Structure Specification

Complete structure specifications and material details.

| Dimension | Net weight | Glue inlet | The material of part in contact with glue | Material of striker |

|---|---|---|---|---|

| 99x78x37.5(mm) | 350g | SS connector | SUS 304 | Tungsten steel/ceramic |

| Heating range | Heating power | Fluid seal | Drive mode | Material of Nozzle |

| Room temperature to 180°C | 80 W | PEEK/PE/PTFE | Piezoelectric | Tungsten steel/ceramic |

| Minimum dot size | Maximum dispensing frequency | Adaptable glue type | Temperature environment | |

| 3NL | 500HZ | Adhesives,binderswater solvents, etc. | 0-45° | |