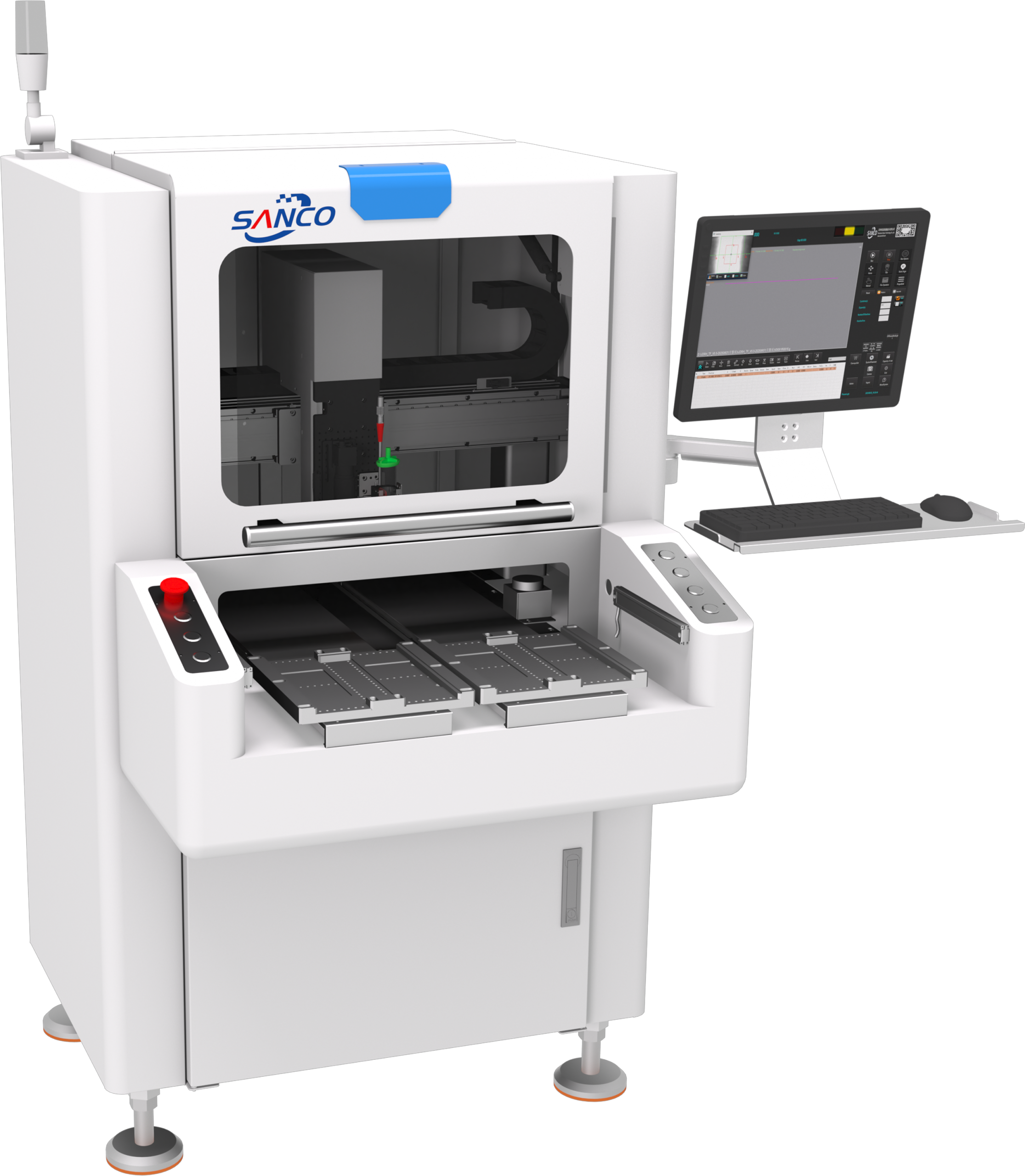

Dispensing Machine

Offline High Speed Dispensing Machine

LM-5331 series - Cost-effective, simple design, suitable for multi-standard circuit boards and substrates with high-precision linear motors.

Product Description

LM-5331 series is offline high-speed dispensing equipment with advantages of: obviously cost-effective, simple design, suitable for multi-standard circuit boards and substrates.

XYZ three-axis motion modules are assembled with high-precision linear motors and servo motors. The human-computer interaction interface is simple and intuitive, making operation efficient and user-friendly.

KEY FEATURES

Advanced technology and precision engineering for reliable dispensing performance

Windows Control System

Using computer control, Windows operating system, fault sound and light alarm and menu display

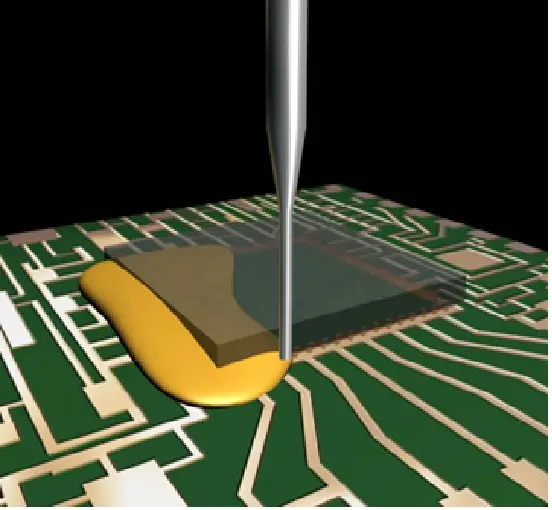

CCD Vision Positioning

CCD Vision Positioning System for accurate alignment and precise dispensing placement

Servo Motor Control

Using servo motor for XYZ + motion control card for high-speed and high-precision operation

Professional Structure

Professional motion control and high-quality module structure lay a solid foundation for stability

Cast Iron Chassis

The cast iron chassis and gantry provide a strong guarantee for the stability of operation

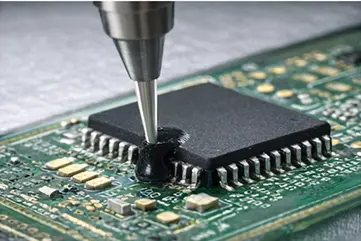

Multiple Valve Options

Can be equipped with: pneumatic injection valve, piezoelectric valve, screw valve, etc

Flexible Programming

Directly import any brand of placement machine files, or online visual programming

Laser Height Detection

Optional laser height detection system, Z-axis height can be automatically calibrated after workpiece is deformed

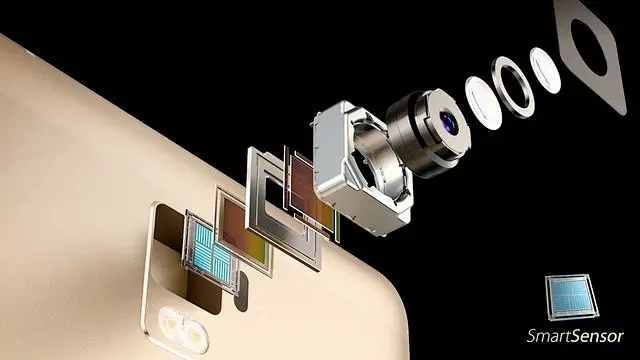

Applications

Versatile dispensing solutions for diverse manufacturing requirements

Detailed Parameters

Complete technical specifications for all model variants.

| Item | Specification and description | |

|---|---|---|

| LM-5331DX | LM-5331X | |

| Model No. | LM-5331DX | LM-5331X |

| Dimension | L=900mm W=950mm H=1550mm |

L=900mm W=950mm H=1550mm |

| Net weight | 400kg | 400kg |

| Control | IPC+Motion control card | IPC+Motion control card |

| Software | Sanco software+Windows | Sanco software+Windows |

| Spindles Drive | Servo motor for X Y Z | Servo motor for X Y Z |

| Distance area | X:500mm Y:600 Z:75m | X:560mm Y:600 Z:75mm |

| Dispensing Range | X:250 Y:300 Z:75(mm) (Dual platform) |

X:500 Y:300 Z:75(mm) (Single platform) |

| Valve quantity | 1 pcs(Standard) | 1 pcs(Standard) |

| Maximum Speed X/Y/Z | 1000mm/s for XY, 300mm/s Z axis | 1000mm/s,XY, 300mm/s Z axis |

| Repeatability accuracy | ±0.02 mm | ±0.02 mm |

| Material packing | 30CC/55CC | 30CC/55CC |

| Work method | Manual load and unload the products | Manual load and unload the products |

| Positioning | High precision CCD visual positioning | High precision CCD visual positioning |

| Alarm | Sound and light alarm | Sound and light alarm |

| Power suppy | 220V 50/60HZ | 220V 50/60HZ |

| Air pressure | >0.5MPa | >0.5MPa |

| Total power | 1100W | 1100W |

| Work platform | Dual platform | Single platform |